This is where truly bespoke and unique floors are created. Starting with an unfinished, raw floor board as your canvas, add or remove texture to the surface and build layers of colour to create the floor of your dreams. We can only show you a representation of what the floor could look like, but order a sample and we’ll create the real thing for you! Once the sample is approved, we can make your dream floor a reality! Quick tip: the rougher the texture, the more intense (deep or light) the overall colour.

The bespoke process

At Rafe Olsen, we have the ability to produce virtually any floor finish you desire. This starts with a few basics from which the unique journey begins.

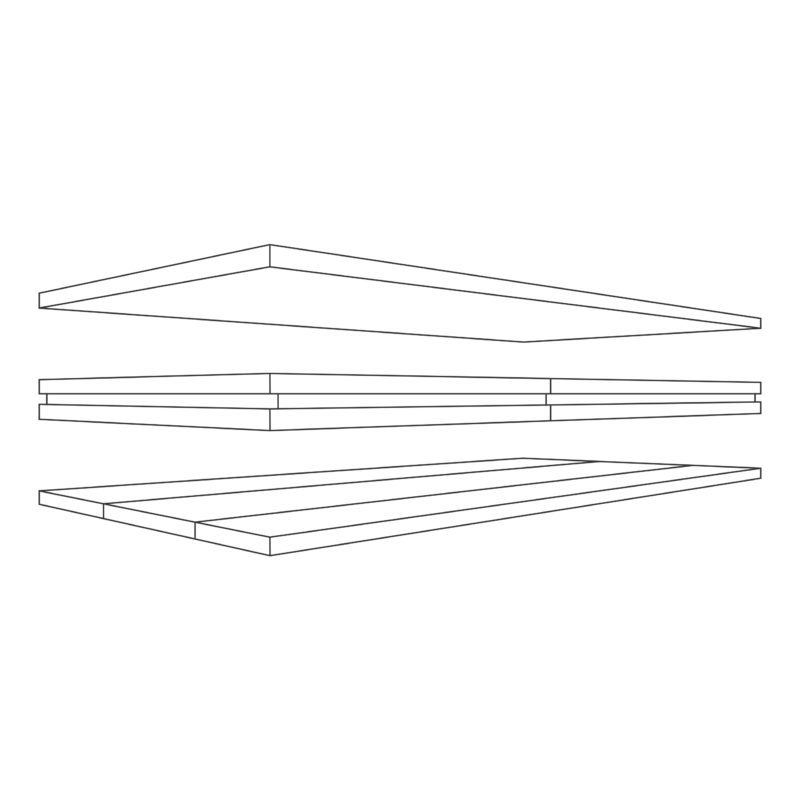

The process is relatively linear; choose a width of floor board to use as the canvas, decide how you would like the surface to appear (and importantly feel), add a base colour (or don’t) and finish with a coloured (or clear) oil. The tools to make the selections to produce your dream floor can be found above on the flooring generator. We can show you an impression of how the floor may look and from this you can order a sample to try in situ. Don’t like anything you see? Contact us! We can produced virtually anything you can imagine!

At this point, it is worth pointing out that our opinion is; all fully bespoke designed floors should only be ordered after seeing an actual sample. Rafe Olsen bespoke floors are entirely non-returnable once work has begun. Please see our T&Cs for more information.